An overview of this versatile material

Versatility

Stainless steel is a metal that’s all pervasive – strong, robust and flexible – but so widely used that it all-to-often blends competently and unobtrusively into the background. Here I attempt to provide insight into its versatility as a remarkable building material; from handsome structural elements to the more whimsically formed art pieces, furniture, fittings and speciality metal works.

Structural stainless steel beams by Kivort Steel

Tom Dixon’s Etch Web light fitting constructed from stainless steel

As iron alloys with elements such as carbon, chromium, nickel, molybdenum, copper, manganese and various other elements to stay true to the environment it inhabits, we see its adaptability, longevity, and sustainability making it, at least in my book, a one-of-a-kind material—a “super alloy”.

Grades and types

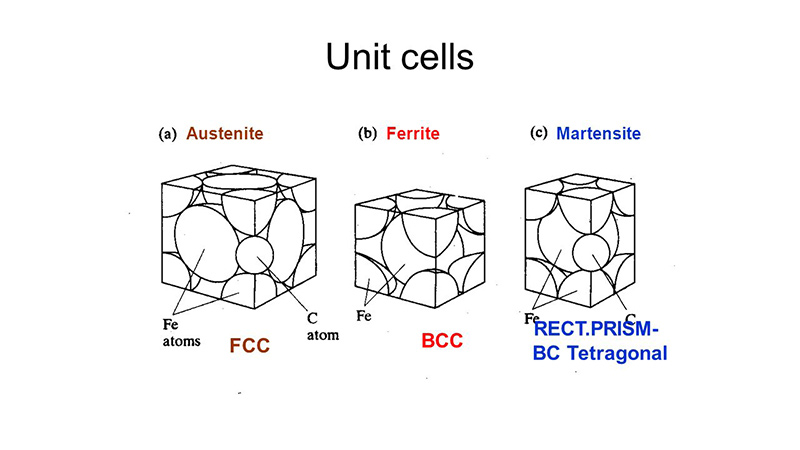

Stainless steel or inox (from the French inoxydable) comes in different grades, forms and finishes and is used primarily in environments where both the properties of steel and corrosion resistance are a prerequisite. Austenitic steels (meaning the iron has ‘face-centered’ cubic crystals, as opposed to say ferritic or martensitic where the structures are different), are the most commonly used form in the construction industry.

Diagram by Abdulkader Alshereef, Lead Quality Engineer at Bechtel OG&C Inc.

If one were to consider some of the unique properties of stainless steel—strength, tensility, high resistance to corrosion and fire, it is no surprise why it is one of the most popular and the costeffective option when it comes to material selection in the construction industry. These core properties provide a high return on investment over the total life of the project.

Qualities

Chemical compositions in stainless steel are manipulated and tailored to suit their environment. Certain grades resist corrosion. The various constituent elements present, in combination, react with oxygen in water and air to form a thin, protective layer or barrier. Experts allege this film to be thinner than a wavelength of light which makes it almost invisible to the naked eye. This allows it to be both aesthetically pleasing and low maintenance. Certain speciality grades can retain strength at high temperatures which means they are fire and heat resistant. The austenitic micro-structures also provide for toughness in high temperatures as well as at temperatures below freezing. All of the above make it a much sought-after and widely-specified building material.

Stainless steel snow plough by Fisher used in sub-zero temperatures

The Unified Numbering System for stainless steel

When specifying stainless steel it is important to specify its UNS number (Unified Numbering System) associated with the specific alloy and grade alongside the domestic standard to avoid confusion. The UNS numbers are standardized specifications for internationally-recognized chemistry requirements. This means that there are varying elemental weight percentages for the different types of stainless steel. So, in order to withstand specific environmental conditions, for example, it has internationally-accepted measures of content: the proportion of chromium, the amount of nickel, carbon, copper, and so on . For example, one type of steel produced worldwide is sometimes referred to as “18-8” steel due to its 18% chromium and 8% nickel content. Another example is “surgical stainless” where a certain percentage of molybdenum is alloyed to make the stainless steel more resistant to corrosive environments such as acidic vapors or salt water. Similarly, another subtype is marine stainless which can combat potential corrosion caused by the ravages of salt water and maritime weather conditions.

Surgical instruments in surgical stainless steel

Ease of use

Stainless steel, therefore, comes in many types, from decorative interior and exterior applications to those that require high performance in stress- and-strain situations. It has a broad range of surface finishes, too, from standard to speciality finishes and coatings—brushed, patterned or coloured, powder or PVD (physical vapour deposition).

Its relative simplicity, in production, forming and finishing terms, and the abundant availability of its core materials, iron ore and scrap, make it a genuinely sustainable material. All these factors contribute to the versatile nature of stainless steel. They also contribute to making the task of the designer, fabricator and end-user a relatively easy and pleasurable one.