We look at how the use of screen materials is developing

The trend of the past two decades for covering entire buildings in glazing has had negative environmental implications that has required architects to develop new approaches. This has led to the development of bioclimatic architecture: rather than creating glass towers that trap heat and rely on mechanical cooling, architects are now incorporating systems in their building designs that provide protection from summer sun, reduce winter heat loss, and make use of the environment for heating, cooling and lighting buildings.

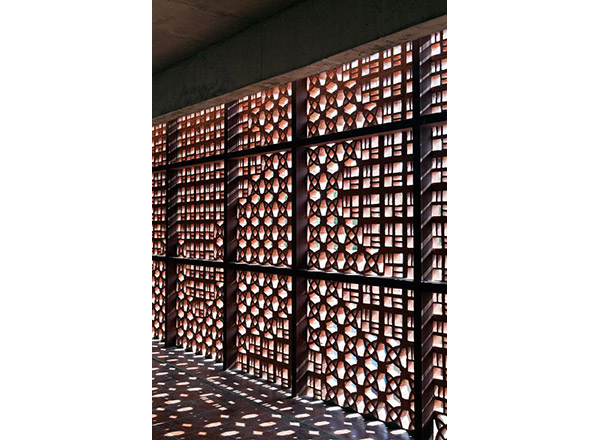

The practice of screening exterior façades from sun or winter storms is an old concept that has regained popularity with the development of bioclimatic design. Perforated walls, panels and screens have been used for centuries as a way to control the level of light entering a building or to offer privacy to the occupants. Intricately patterned screens are a typical feature of many buildings in parts of Asia, the Middle East and North Africa, where they would traditionally have been cut by hand by skilled craftsmen. These traditional applications for perforated surfaces have inspired and informed contemporary architects interested in developing bioclimatic façades. Increasingly they are specifying a second layer of screens on the outside the building that acts as a double envelope or second skin to achieve the building’s energy reduction goals. These second skin façades can cost effectively reduce energy consumption while improving the building’s appearance at a much lower cost than modifying the load bearing walls.

Façade screen detail. DPS kindergarten, Bangalore, Khosla Associates

Photo Shamanth Patil jr

Changing the face of contemporary architecture

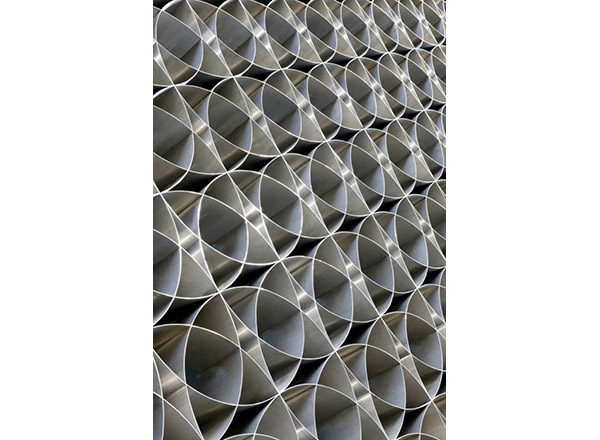

The functions of perforations have remained largely the same, but the materials and methods of manufacture have altered considerably. No longer cut or carved by hand, developments in cutting edge technologies mean that detailed customized patterns can now be quickly and easily etched into various materials for interior or exterior use. With new technologies come new options for architects

and designers interested in exploring the potential for perforations to tell stories and create statements. It is now possible to produce detailed patterned surfaces quickly and easily and on a scale large enough to wrap entire buildings. As a result perforated stainless steel or aluminium screens have become a major decorative element for building facades for which architects can develop bespoke designs that add a distinctive personality to a building’s exterior, as well as performing an important bioclimatic functions.

Stainless steel screen detail, Moroccan Bank BMCE’s headquarters, Foster + Partners.

Photo Nigel Young

Double skin façades are set typically set between 0.2 and 4.5 meters away of the building’s external façade. The intermediate space between the perforated metal sunscreens and the building’s facade provide shading and resistance to heat loss and gain. In residential buildings they can become outdoor walkways that connect the interior spaces or simply terrace areas. These double skins can be active, computer controlled systems so that by adjusting to the sun’s rays they maximise the benefits of solar radiation whilst minimizing heat gain. Passive second skin façades are simple static sunscreens that are not linked to the building’s energy system. Vertical green ‘living’ façades present a low technology option that passively adjust to the seasons. They are made up of woven mesh screens in which deciduous climbers are trained shielding windows from summer sun and after the leaves fall allowing winter light to warm the buildings.

Perforated façades enable interior spaces to benefit from natural light, filtered in such a way that it reduces the glare of direct sunlight and resulting in an environment that is conducive to relaxation and working. Whether used internally or externally, perforations create a dialogue between spaces; obscuring or inviting views as required and keeping temperature and brightness at a pleasant and practical level. Shade and privacy will continue to be the key practical purposes of perforations, but the potential applications are greater than ever.

Stainless steel screens: sustainable design benefits

Architects can find perforated metal screens in a whole range of decorative metals such as aluminium, (powder-coated or anodised in any colour), brass, copper, raw steel, stainless steel (mirror polished or brushed) or titanium. However when using perforated metal screens for external applications, stainless steel provide much higher corrosion resistance than other common architectural metals particularly when there is pollution or exposure to coastal salt.

With the use of stainless steel there is also the possibility of using PVD coated material which adds the opportunity to use a variety colours and finishes as well as making the surface even more durable.

Stainless steel also has extremely low runoff levels and is not toxic to the environment. For this reason stainless steel lends itself very well to passive green façades. Once the plants are fully grown the supporting structure needs to offer a high level of strength to withstand wind loads so again stainless steel is the ideal choice.

Opening up a range of creative possibilities

To conclude perforated metal screens are an excellent means of achieving sustainable design objectives. More widely, perforated materials are also very versatile. Although we have focused in this article on external applications, perforated metal screens can also be specified as interior design elements to create see-through partitions or sound-absorbing surfaces. From lightweight decorative elements to load-bearing structural components, perforated metal offers unique opportunities to combine strength, functionality and beauty.

Dark walls overlaid with laser-cut high polished stainless steel panels in the Uzbekistan International Forums Palace. Designed by Ippolito Fleitz Group for the Republic of Uzbekistan